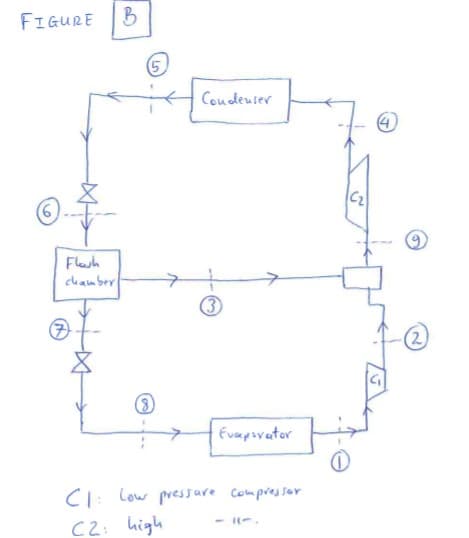

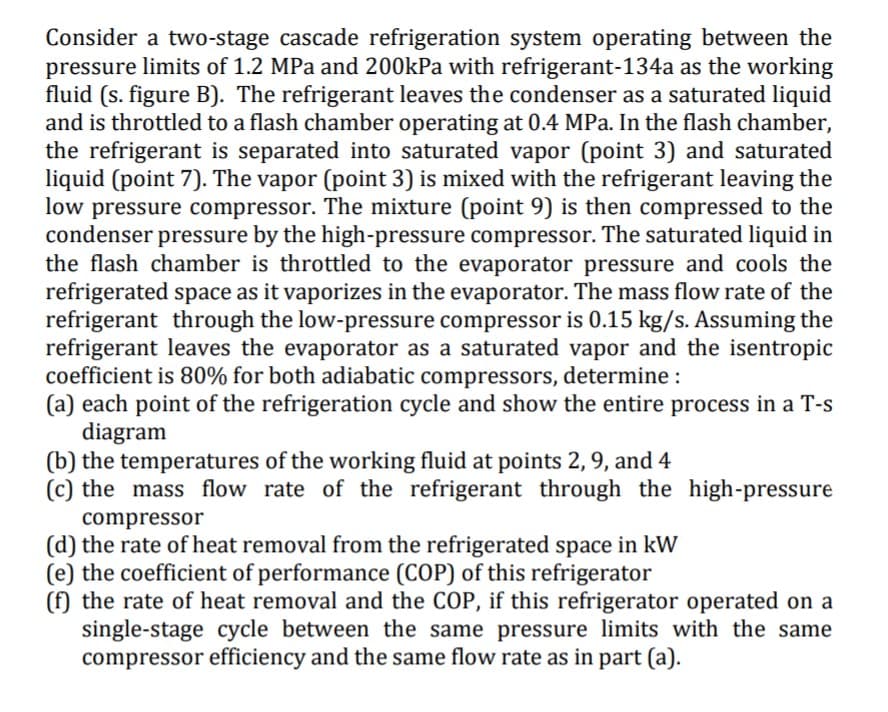

Consider a two-stage cascade refrigeration system operating between the pressure limits of 1.2 MPa and 200kPa with refrigerant-134a as the working fluid (s. figure B). The refrigerant leaves the condenser as a saturated liquid and is throttled to a flash chamber operating at 0.4 MPa. In the flash chamber, the refrigerant is separated into saturated vapor (point 3) and saturated liquid (point 7). The vapor (point 3) is mixed with the refrigerant leaving the low pressure compressor. The mixture (point 9) is then compressed to the condenser pressure by the high-pressure compressor. The saturated liquid in the flash chamber is throttled to the evaporator pressure and cools the refrigerated space as it vaporizes in the evaporator. The mass flow rate of the refrigerant through the low-pressure compressor is 0.15 kg/s. Assuming the refrigerant leaves the evaporator as a saturated vapor and the isentropic coefficient is 80% for both adiabatic compressors, determine: (a) each point of the refrigeration cycle and show the entire process in a T-s diagram (b) the temperatures of the working fluid at points 2, 9, and 4 (c) the mass flow rate of the refrigerant through the high-pressure compressor (d) the rate of heat removal from the refrigerated space in kW (e) the coefficient of performance (COP) of this refrigerator (f) the rate of heat removal and the COP, if this refrigerator operated on a single-stage cycle between the same pressure limits with the same compressor efficiency and the same flow rate as in part (a).

Consider a two-stage cascade refrigeration system operating between the pressure limits of 1.2 MPa and 200kPa with refrigerant-134a as the working fluid (s. figure B). The refrigerant leaves the condenser as a saturated liquid and is throttled to a flash chamber operating at 0.4 MPa. In the flash chamber, the refrigerant is separated into saturated vapor (point 3) and saturated liquid (point 7). The vapor (point 3) is mixed with the refrigerant leaving the low pressure compressor. The mixture (point 9) is then compressed to the condenser pressure by the high-pressure compressor. The saturated liquid in the flash chamber is throttled to the evaporator pressure and cools the refrigerated space as it vaporizes in the evaporator. The mass flow rate of the refrigerant through the low-pressure compressor is 0.15 kg/s. Assuming the refrigerant leaves the evaporator as a saturated vapor and the isentropic coefficient is 80% for both adiabatic compressors, determine: (a) each point of the refrigeration cycle and show the entire process in a T-s diagram (b) the temperatures of the working fluid at points 2, 9, and 4 (c) the mass flow rate of the refrigerant through the high-pressure compressor (d) the rate of heat removal from the refrigerated space in kW (e) the coefficient of performance (COP) of this refrigerator (f) the rate of heat removal and the COP, if this refrigerator operated on a single-stage cycle between the same pressure limits with the same compressor efficiency and the same flow rate as in part (a).

Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Chapter1: Introduction

Section: Chapter Questions

Problem 1.1P

Related questions

Question

please solve EF

Transcribed Image Text:FIGURE

(5

Coudeuser

Flesh

chamber

(3

(8)

Evapovator

CI: Low pressare Compressor

C2: high

Transcribed Image Text:Consider a two-stage cascade refrigeration system operating between the

pressure limits of 1.2 MPa and 200kPa with refrigerant-134a as the working

fluid (s. figure B). The refrigerant leaves the condenser as a saturated liquid

and is throttled to a flash chamber operating at 0.4 MPa. In the flash chamber,

the refrigerant is separated into saturated vapor (point 3) and saturated

liquid (point 7). The vapor (point 3) is mixed with the refrigerant leaving the

low pressure compressor. The mixture (point 9) is then compressed to the

condenser pressure by the high-pressure compressor. The saturated liquid in

the flash chamber is throttled to the evaporator pressure and cools the

refrigerated space as it vaporizes in the evaporator. The mass flow rate of the

refrigerant through the low-pressure compressor is 0.15 kg/s. Assuming the

refrigerant leaves the evaporator as a saturated vapor and the isentropic

coefficient is 80% for both adiabatic compressors, determine :

(a) each point of the refrigeration cycle and show the entire process in a T-s

diagram

(b) the temperatures of the working fluid at points 2, 9, and 4

(c) the mass flow rate of the refrigerant through the high-pressure

compressor

(d) the rate of heat removal from the refrigerated space in kW

(e) the coefficient of performance (COP) of this refrigerator

(f) the rate of heat removal and the COP, if this refrigerator operated on a

single-stage cycle between the same pressure limits with the same

compressor efficiency and the same flow rate as in part (a).

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 3 steps with 36 images

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:

9781285061238

Author:

Lokensgard, Erik

Publisher:

Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:

9780072848236

Author:

Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:

McGraw-Hill Companies, The